Toyota Just In Time Example

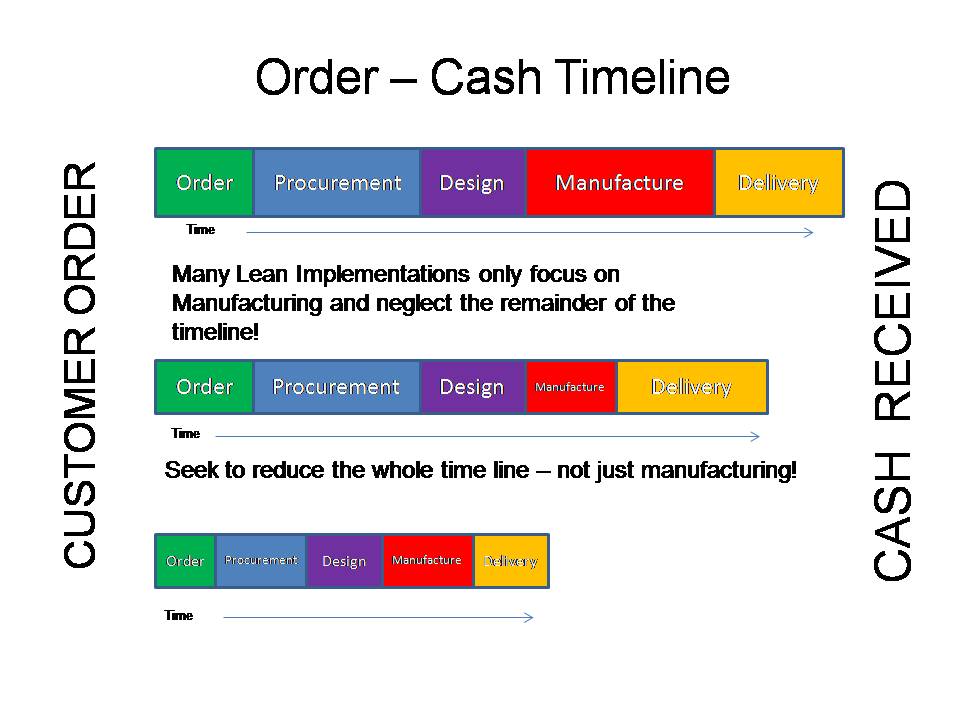

This is the total time required to complete the production process.

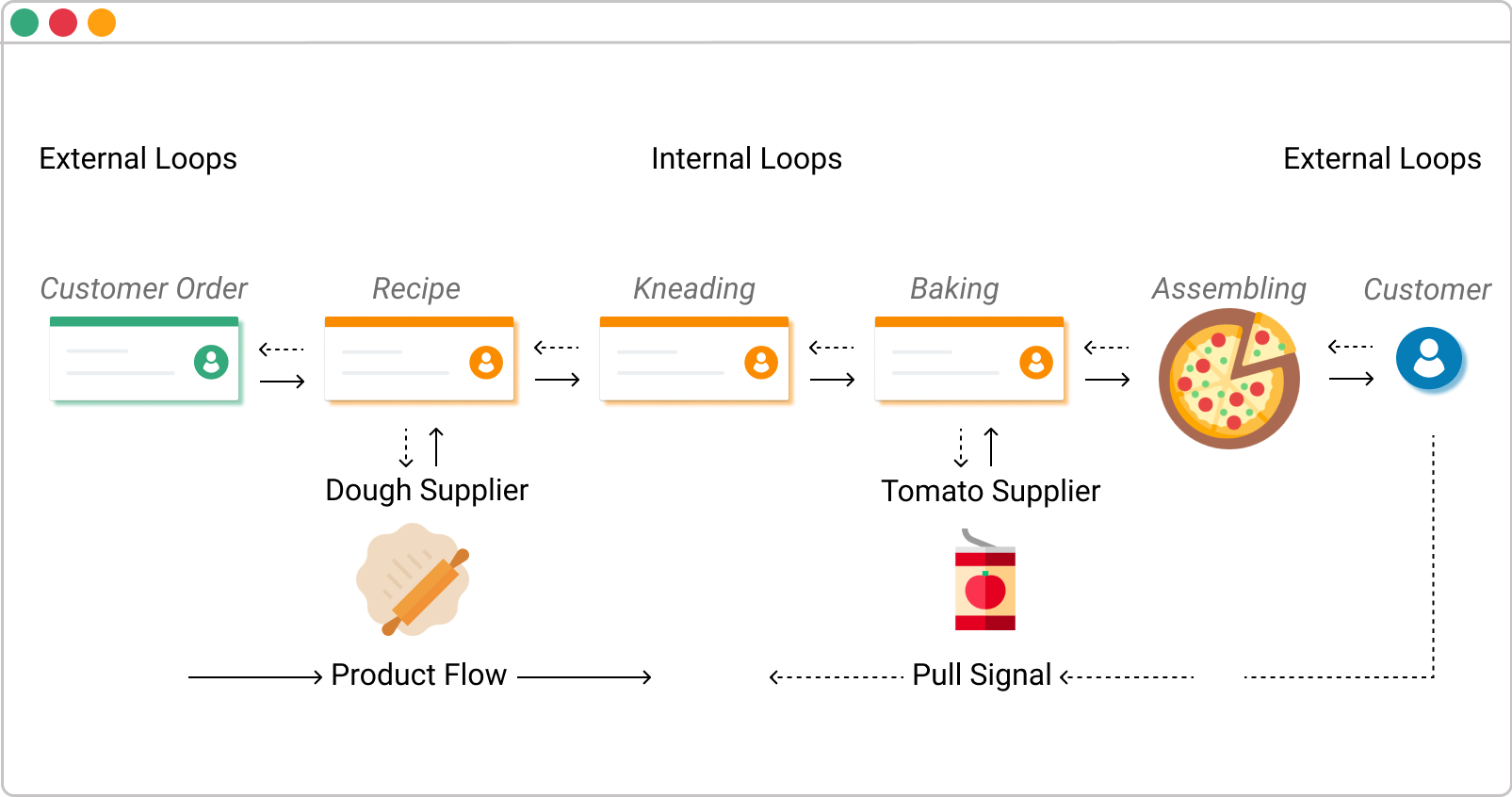

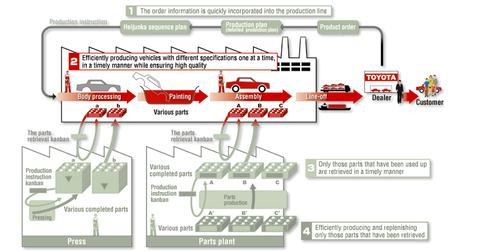

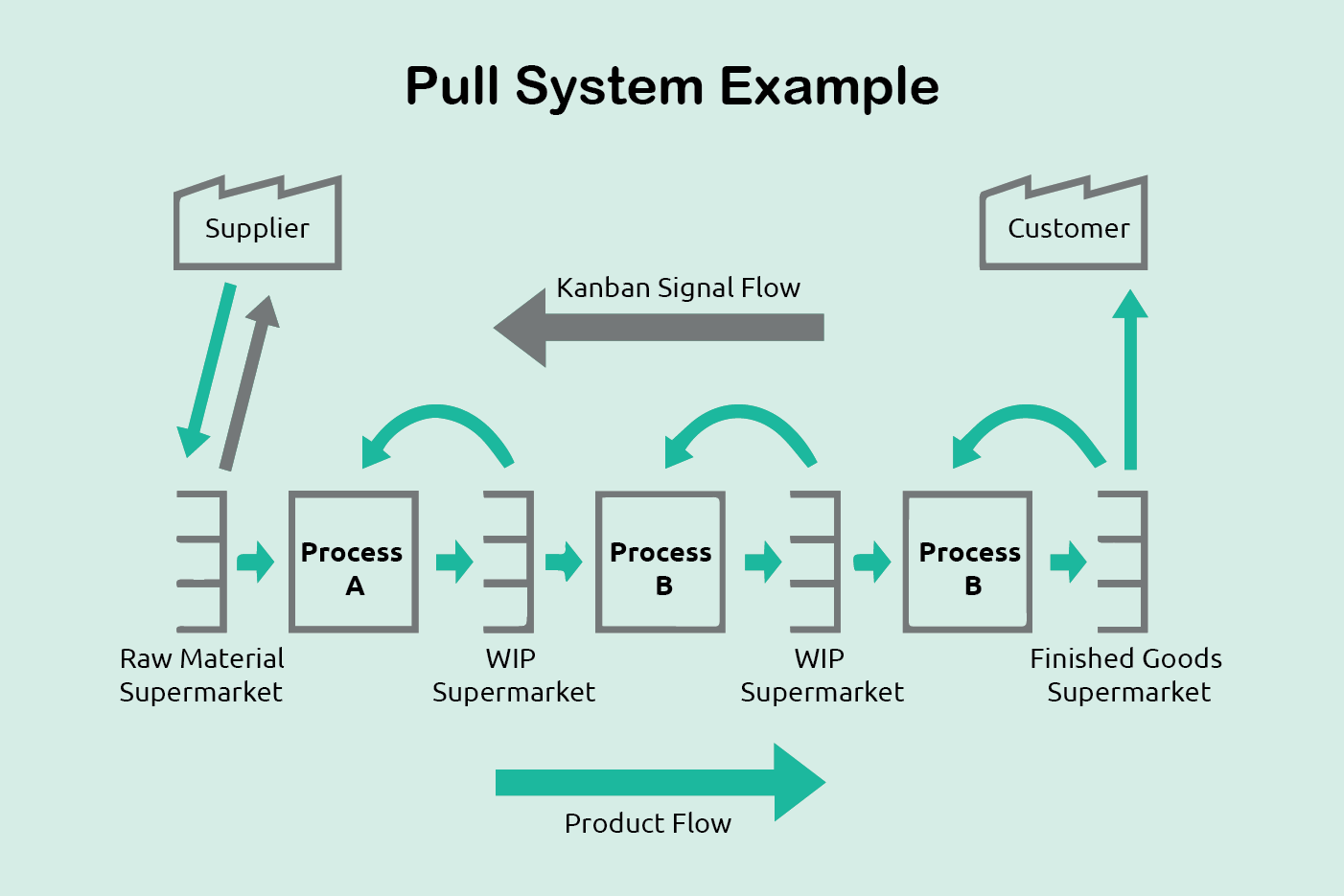

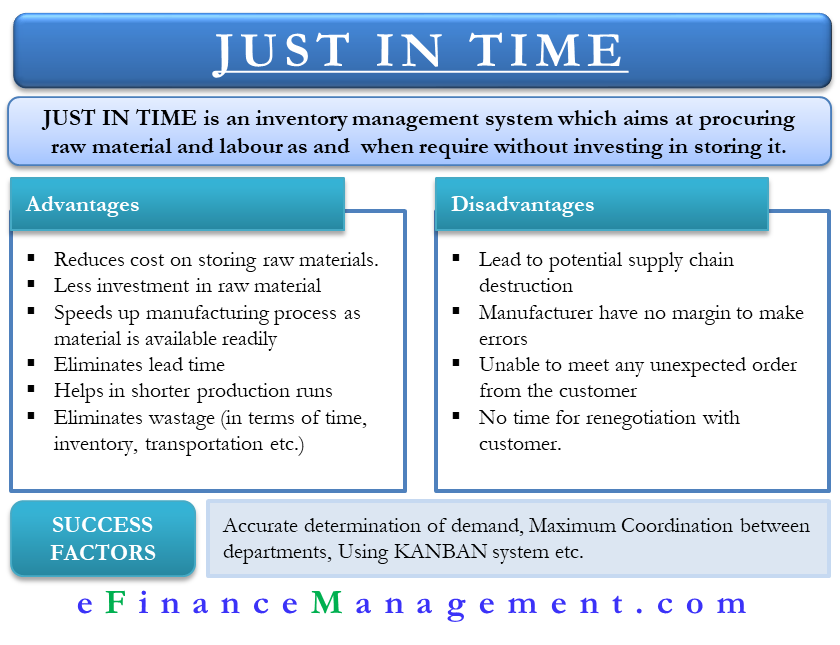

Toyota just in time example. This article focuses on the benefits that companies like toyota dell and harley davidson have gleaned by implementing a just in time jit manufacturing philosophy. The technique of arranging regular small deliveries of exactly the correct amount required was pioneered by toyota. Just in time heijunka kaizen genchi genbutsu nemawashi kanban muda muri mura genba. Jit focus on reducing inventory and throughput.

At the time a sharp decline in auto demand and the high costs of production haunted automakers including toyota. It is the time required to change raw materials to complete products. Although the company installed this method in the 1970s. The just in time jit style of inventory management also sometimes referred to as the toyota production system tps is a strategy of managing inventory inventory inventory is a current asset account found on the balance sheet consisting of all raw materials work in progress and finished goods that a company has accumulated.

The just in time principle entails the continuous improvement of the production process. If you ve ever studied manufacturing it s likely you will have heard of just in time production methods. There are several big name companies in the real world with processes that serve as examples of successful jit systems. Toyota began using the just in time method in 1938.

.jpg)

.jpg)