Proceso Just In Time Toyota

Tujuan sistem produksi just in time jit adalah untuk menghindari terjadinya kelebihan kuantitas jumlah dalam produksi overproduction.

Proceso just in time toyota. Pengertian sistem produksi just in time jit just in time atau sering disingkat dengan jit adalah suatu sistem produksi yang digunakan untuk memenuhi kebutuhan pelanggan pada waktu yang tepat sesuai dengan jumlah yang dikehendaki oleh pelanggan tersebut. However the true potential of this strategy was realized when it integrated this strategy with tps. It is widely used to improve operations. 0 defectos 0 averías 0 stock 0 plazos y 0 burocracia.

Jit focus on reducing inventory and throughput. Claves del proceso just in time en el método jit no solo se suministra lo necesario también se produce lo necesario para garantizar el stock pero sin caer en una sobreproducción. Although the history of jit traces back to henry ford who applied just in time principles to manage inventory in the ford automobile company during the early part of the 20th century the origins of the jit as a management strategy traces to taiichi onho of the toyota manufacturing company. Además se busca cumplir la teoría de los 5 ceros desde el punto de vista del proveedor.

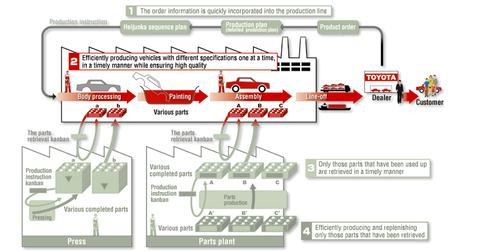

This is the total time required to complete the production process. The process involves ordering and receiving inventory for production and customer sales only as it is needed to produce goods and not before. Toyota and the development of just in time and toyota production system. This philosophy was first developed and perfected within the toyota corporation by taiichi ohno as a means of meeting consumer demands with minimum delays.

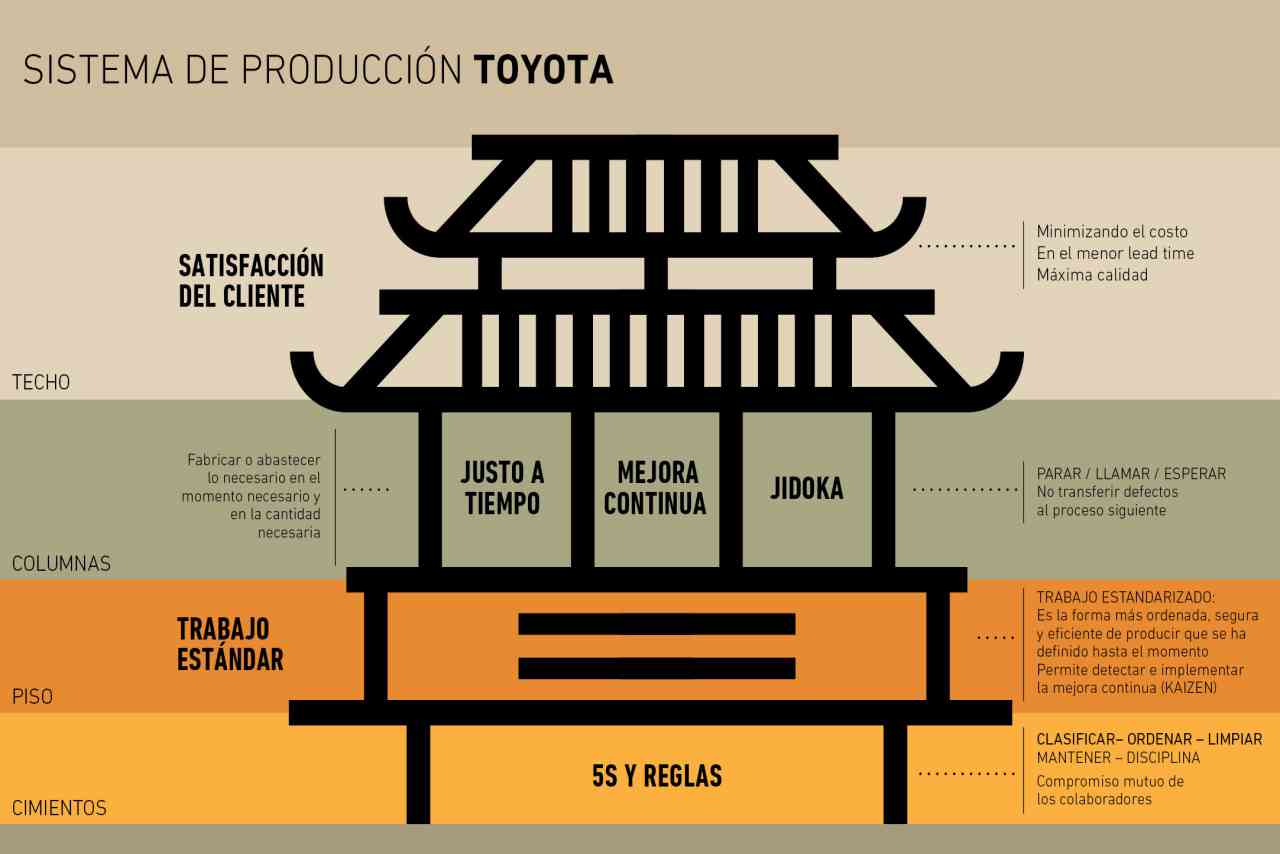

Just in time jit manufacturing also known as just in time production or the toyota production system tps is a methodology aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. The just in time principle entails the continuous improvement of the production process. Jidoka which can be loosely translated as automation with a human touch as when a problem occurs the equipment stops immediately preventing defective products from being produced. Just in time jit is an inventory strategy that strives to improve a business s return on investment by reducing in process inventory and associated carrying costs.

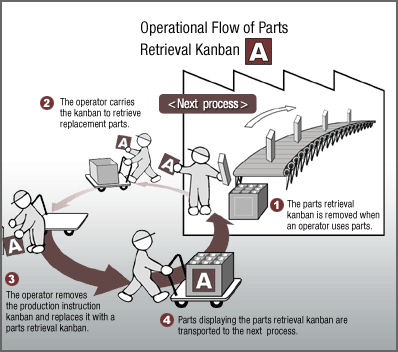

Just in time jit inventory management also know as lean manufacturing and sometimes referred to as the toyota production system tps is an inventory strategy that manufacturers use to increase efficiency. It is the time required to change raw materials to complete products. Its origin and development was mainly in japan largely in the 1960s and 1970s and particularly at toyota. And the just in time concept in which each process produces only what is needed for the next process in a continuous flow.

Productivity improvement making only what is needed when it is needed and in the amount needed producing quality products efficiently through the complete elimination of waste inconsistencies and unreasonable requirements on the production line. The toyota production system tps was established based on two concepts.