Just In Time Toyota Production System And Lean

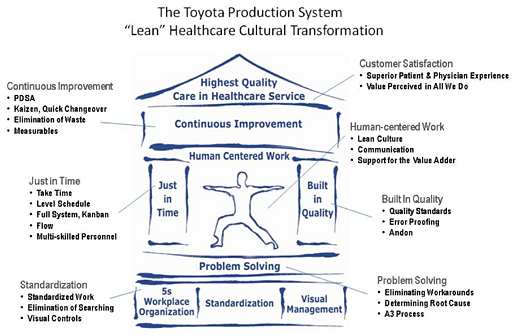

The toyota production system tps is an integrated socio technical system developed by toyota that comprises its management philosophy and practices.

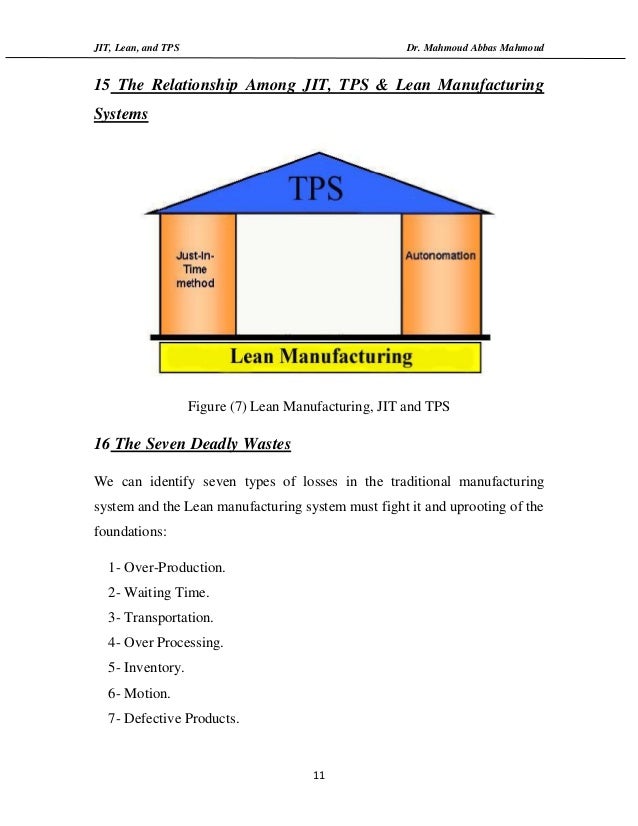

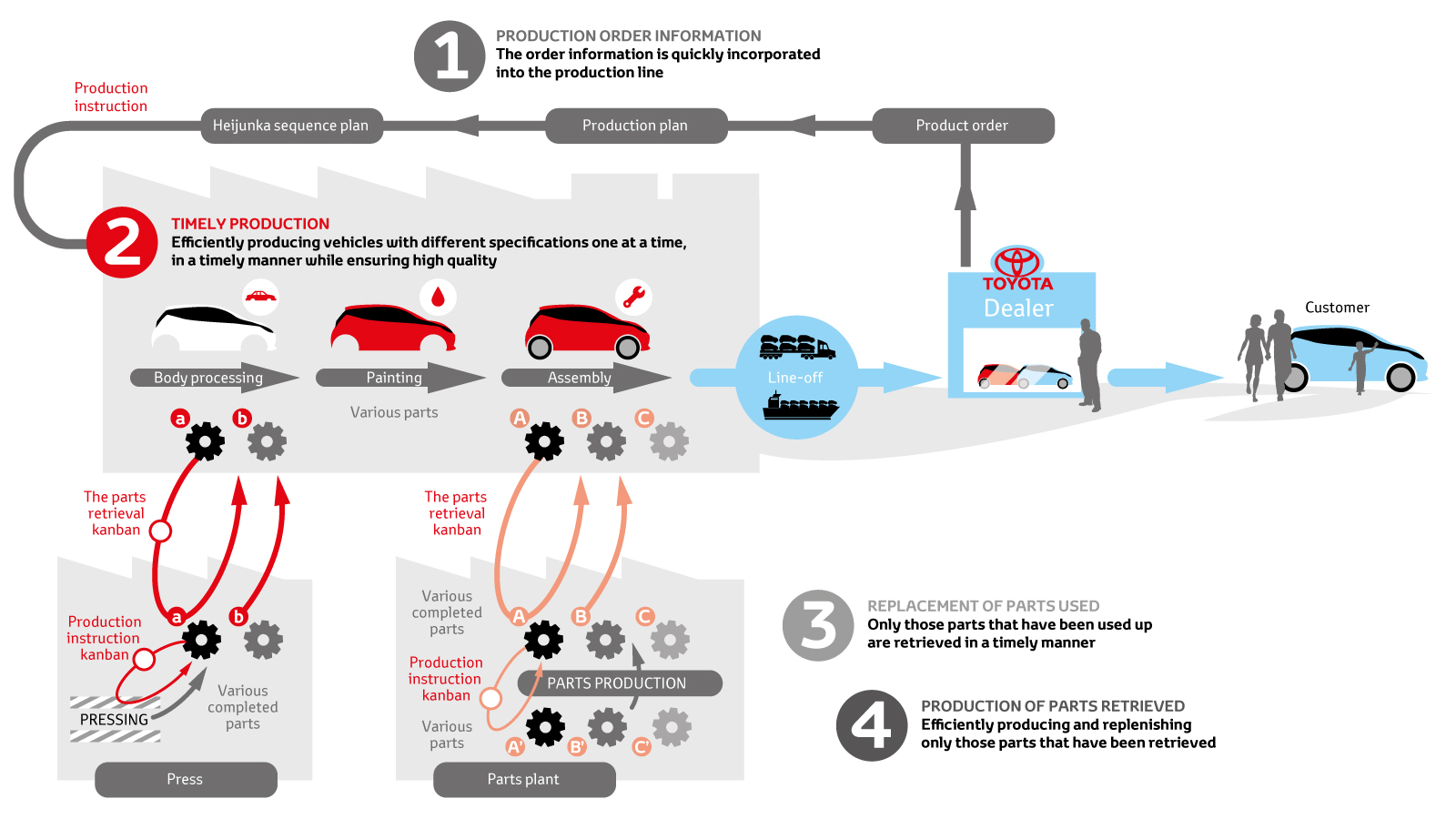

Just in time toyota production system and lean. The process involves ordering and receiving inventory for production and customer sales only as it is needed to produce goods and not before. Just in time jit inventory management also know as lean manufacturing and sometimes referred to as the toyota production system tps is an inventory strategy that manufacturers use to increase efficiency. The toyota production system is a major precursor of lean manufacturing. Just in time production and the identification of the seven wastes along with other tools and techniques became collectively known as the toyota production system.

The system is developed between 1984 and 1975. Many people see the tps as a set of tools and techniques for the elimination of waste and to drive the continuous improvement process. The toyota production was developed between 1948 and 1975 and is now a common management philosophy that is practiced in some of the biggest companies in the world. 13 principles of.

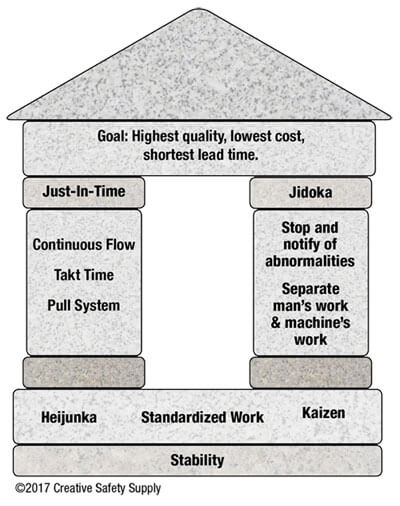

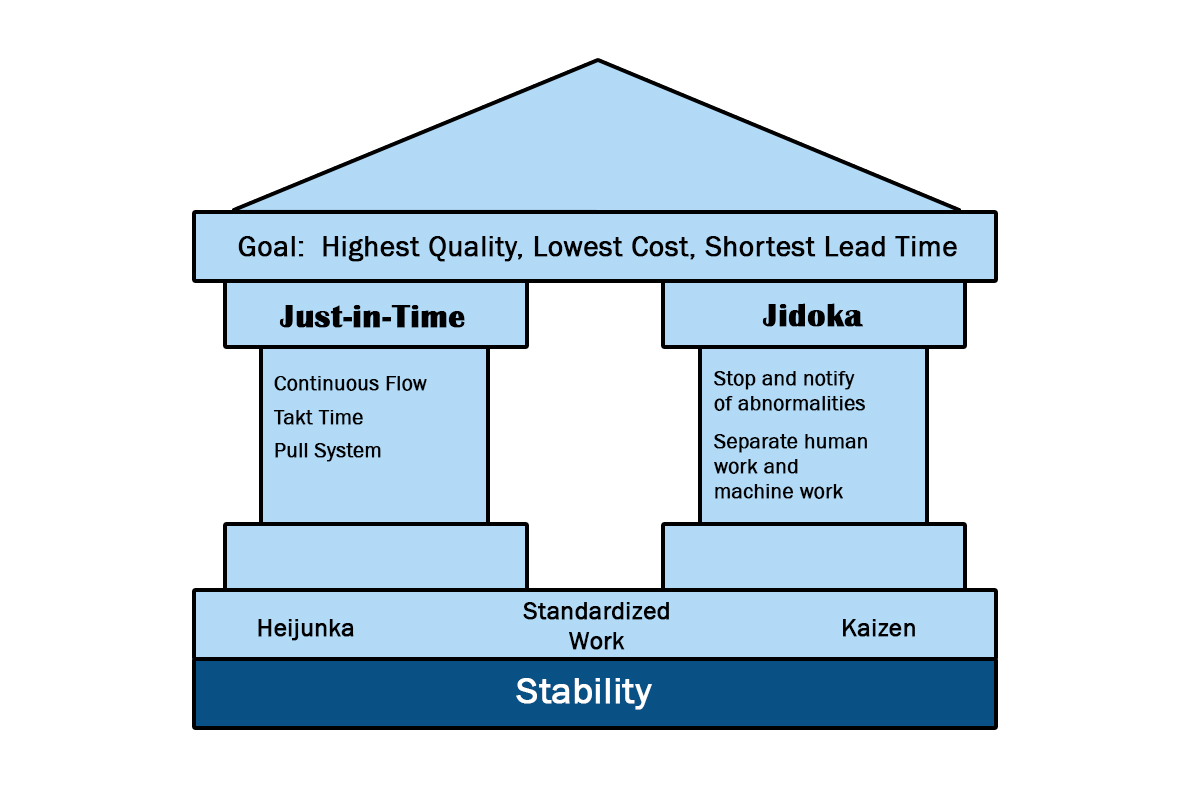

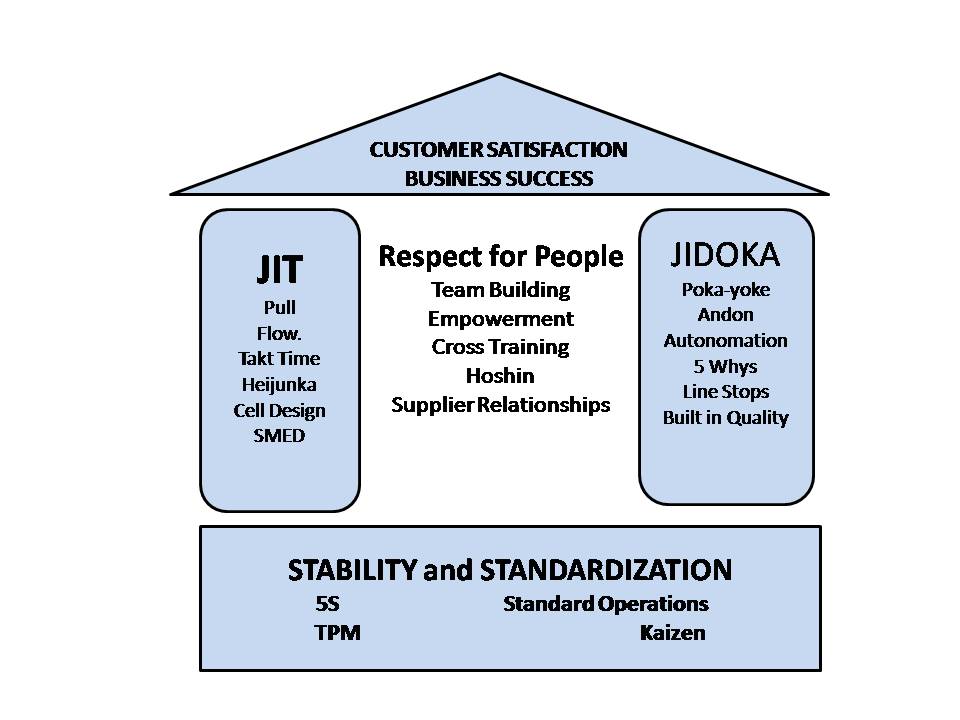

The toyota production system was successful and the term lean production was later coined by an mit research team to describe the revolutionary production and management system they identified at toyota. The tps organizes manufacturing and logistics for the automobile manufacturer including interaction with suppliers and customers. Founded on the conceptual pillars of just in time and jidoka or automation with a human touch the system was first built off the approach created by the founder of toyota sakichi toyoda and his son kiichiro toyoda. A production system based on the philosophy of achieving the complete elimination of all waste in pursuit of the most efficient methods.

The system is also known by the more generic lean manufacturing and just in time production or jit manufacturing this system more than any other aspect of the company is responsible for having made toyota the company it is today. The just in time jit toyota productions system tps and lean operations are some of the production systems used by different companies to improve operations and eliminate wastes. The production system developed by toyota motor corporation to provide best quality lowest cost and shortest lead time through the elimination of waste. Toyota has long been recognized as a leader in the automotive manufacturing and production.

This is at the heart of the toyota production system and the missing element of most lean thinking. Lean manufacturing and just in time production both have their roots in the revolutionary toyota production system. Tps is comprised of two pillars just in time and jidoka and often is illustrated with the house shown at right.

.png)