Just In Time Ejemplo Toyota

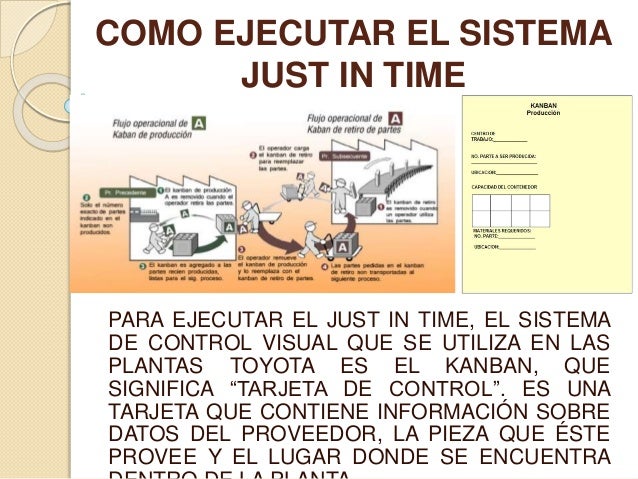

It is widely used to improve operations.

Just in time ejemplo toyota. Toyota began using the just in time method in 1938. If you ve ever studied manufacturing it s likely you will have heard of just in time production methods. This is the total time required to complete the production process. Ellos fueron los verdaderos artífices a los que le debemos hoy en día este sistema jit o just in time.

Origins of just in time management strategy. Jit focus on reducing inventory and throughput. Se atribuye al fundador de la marca japonesa sakichi toyota a su hijo kiichiro y al ingeniero taiichi ohno. The technique of arranging regular small deliveries of exactly the correct amount required was pioneered by toyota.

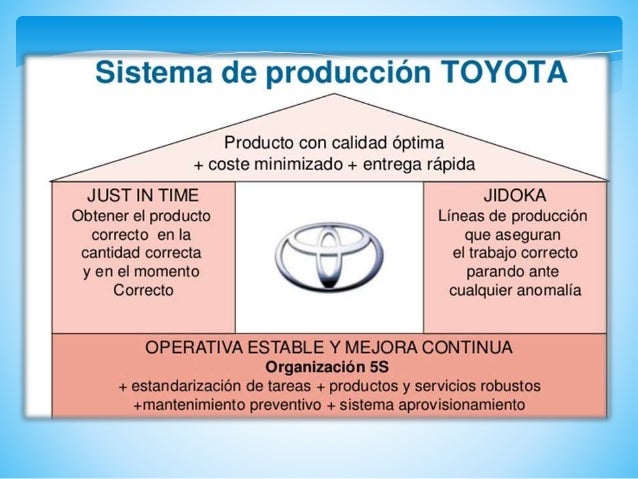

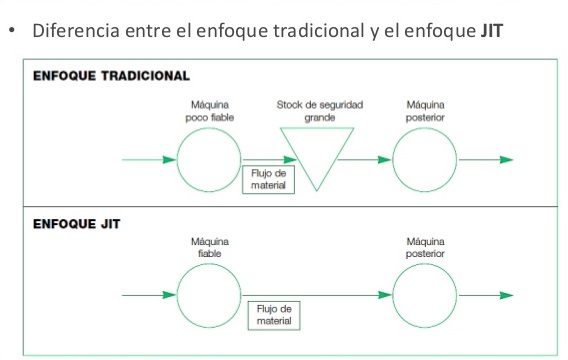

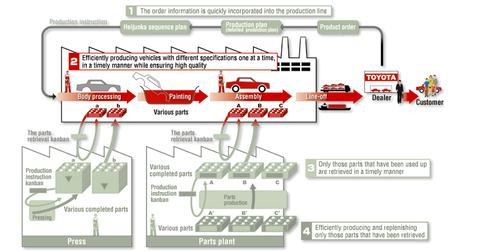

It is the time required to change raw materials to complete products. Productivity improvement making only what is needed when it is needed and in the amount needed producing quality products efficiently through the complete elimination of waste inconsistencies and unreasonable requirements on the production line. Just in time heijunka kaizen genchi genbutsu nemawashi kanban muda muri mura genba. Although the history of jit traces back to henry ford who applied just in time principles to manage inventory in the ford automobile company during the early part of the 20th century the origins of the jit as a management strategy traces to taiichi onho of the toyota manufacturing company.

El sistema de producción de toyota tuvo un origen que merece la pena recordar.