Toyota Just In Time Production

Toyota takes just in time production to another level setting assembly sequence earlier saves inventory space for parts suppliers toyota is overhauling its production process for compacts in.

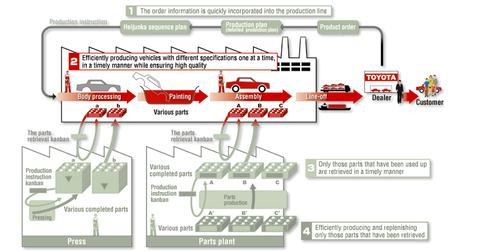

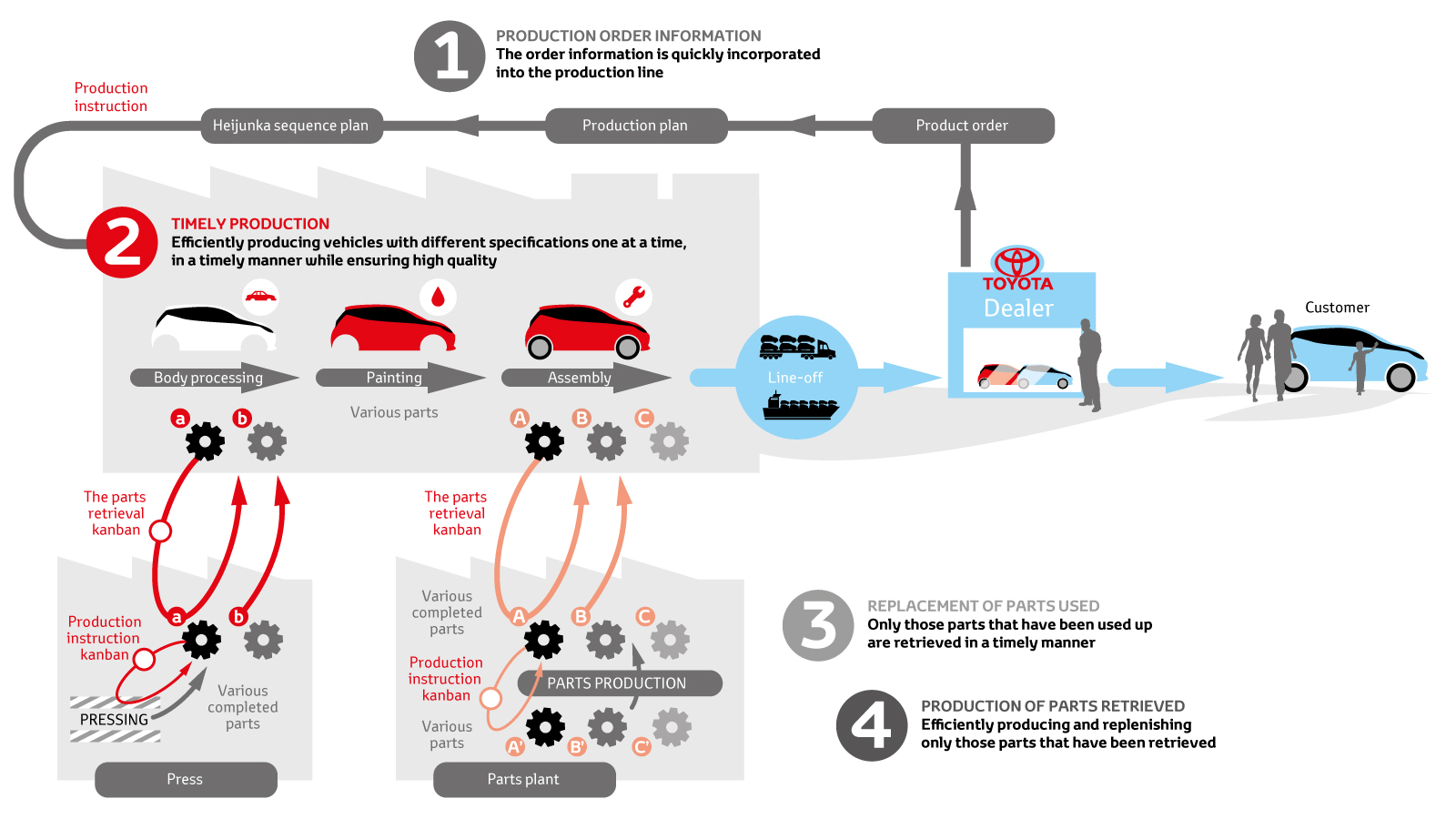

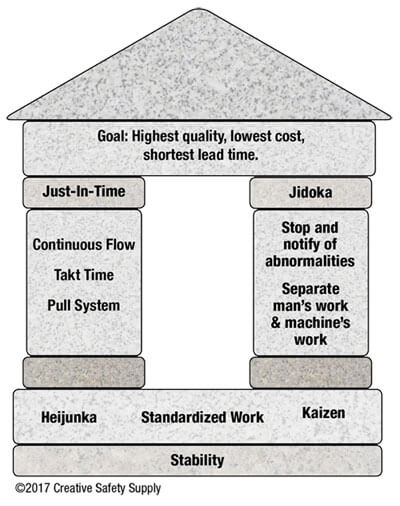

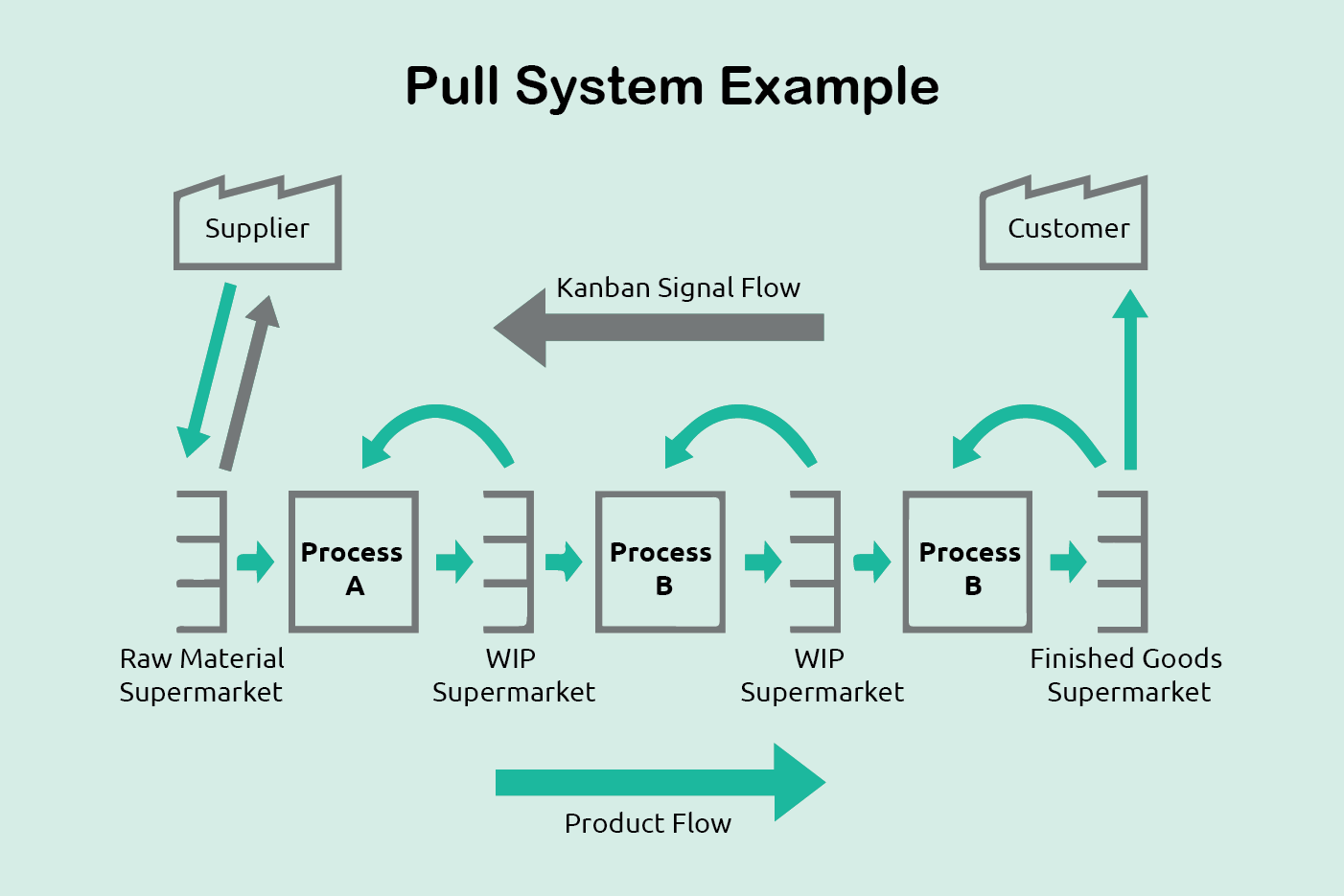

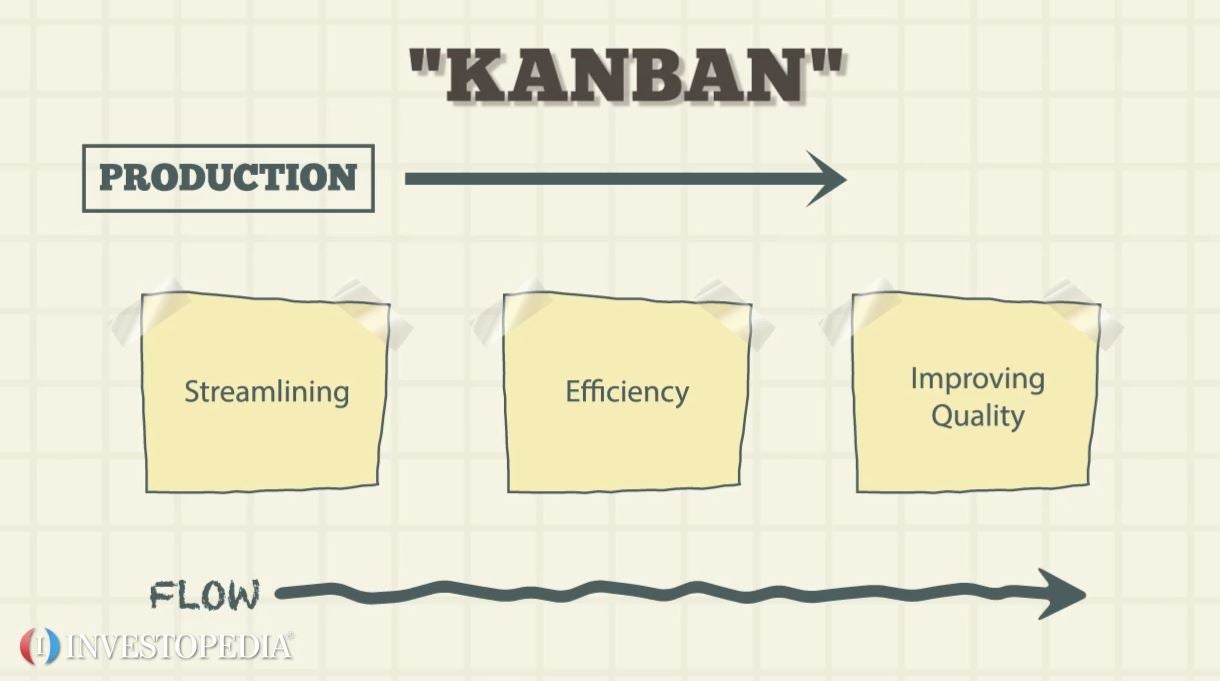

Toyota just in time production. The process involves ordering and receiving inventory for production and customer sales only as it is needed to produce goods and not before. Just in time jit manufacturing also known as just in time production or the toyota production system tps is a methodology aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. Productivity improvement making only what is needed when it is needed and in the amount needed producing quality products efficiently through the complete elimination of waste inconsistencies and unreasonable requirements on the production line. Jit focus on reducing inventory and throughput.

This is the total time required to complete the production process. It is widely used to improve operations. Its origin and development was mainly in japan largely in the 1960s and 1970s and particularly at toyota. Pengertian sistem produksi just in time jit just in time atau sering disingkat dengan jit adalah suatu sistem produksi yang digunakan untuk memenuhi kebutuhan pelanggan pada waktu yang tepat sesuai dengan jumlah yang dikehendaki oleh pelanggan tersebut.

Just in time jit inventory management also know as lean manufacturing and sometimes referred to as the toyota production system tps is an inventory strategy that manufacturers use to increase efficiency. It is the time required to change raw materials to complete products. The just in time jit inventory system is a management strategy that minimizes inventory and increases efficiency. Just in time jit manufacturing is also known as the toyota production system.

Origins of just in time management strategy. Although the history of jit traces back to henry ford who applied just in time principles to manage inventory in the ford automobile company during the early part of the 20th century the origins of the jit as a management strategy traces to taiichi onho of the toyota manufacturing company. However the true potential of this strategy was realized when it integrated this. Tujuan sistem produksi just in time jit adalah untuk menghindari terjadinya kelebihan kuantitas jumlah dalam produksi overproduction.

A production system based on the philosophy of achieving the complete elimination of all waste in pursuit of the most efficient methods. The just in time principle entails the continuous improvement of the production process.

.jpg)