Toyota Just In Time Inventory

.jpg)

Just in time jit is an inventory management system intended to increase production efficiency and profit by controlling inventory and associated costs.

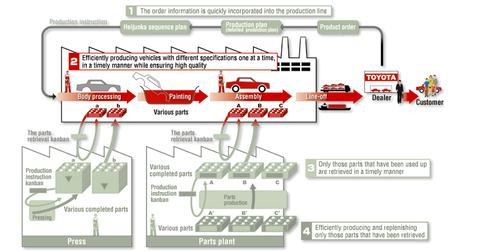

Toyota just in time inventory. Origins of just in time management strategy. Kanban was originally developed at toyota in the1950 s as a way to manage material flow on the assembly line. Although the history of jit traces back to henry ford who applied just in time principles to manage inventory in the ford automobile company during the early part of the 20th century the origins of the jit as a management strategy traces to taiichi onho of the toyota manufacturing company. Just in time jit manufacturing is also known as the toyota production system.

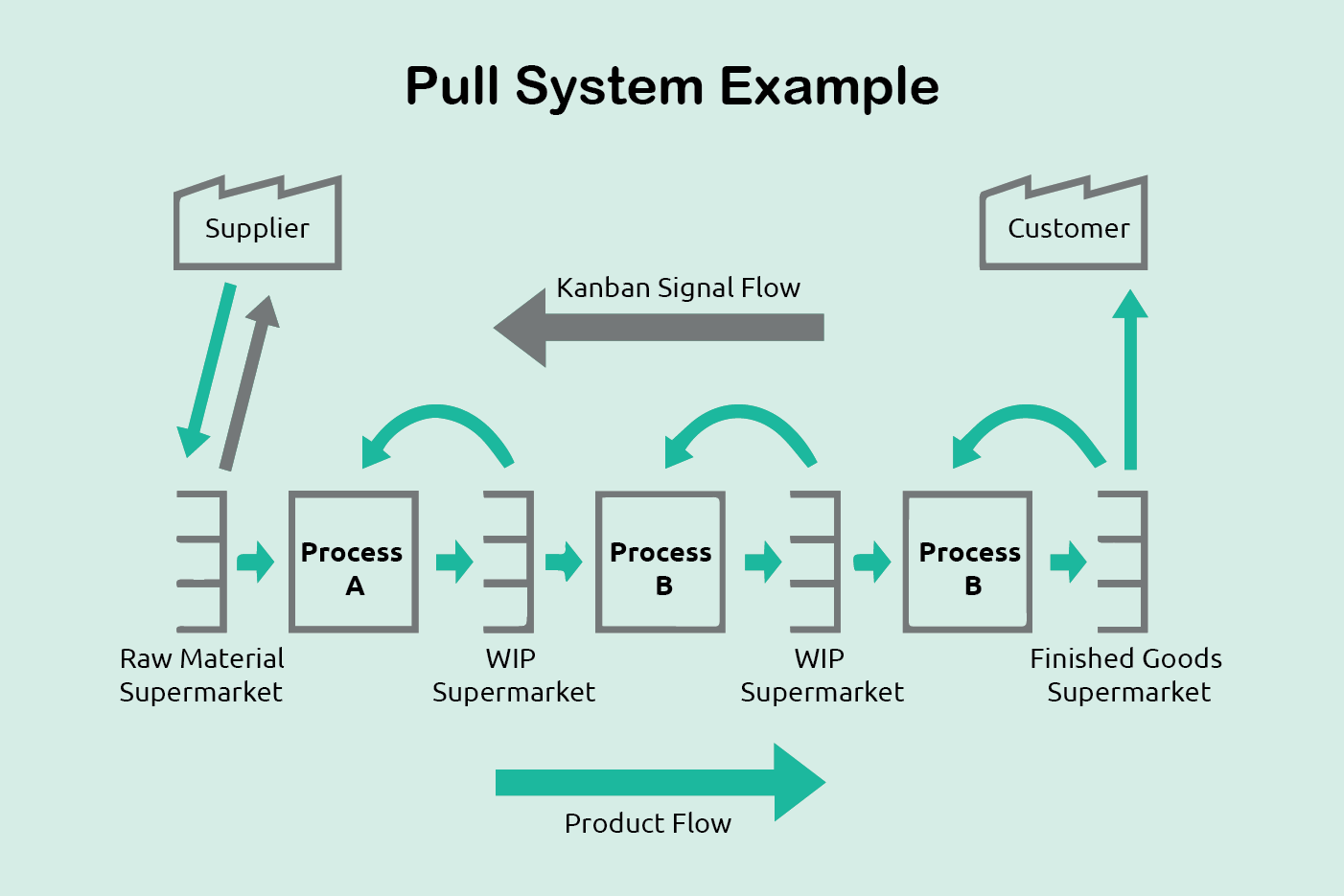

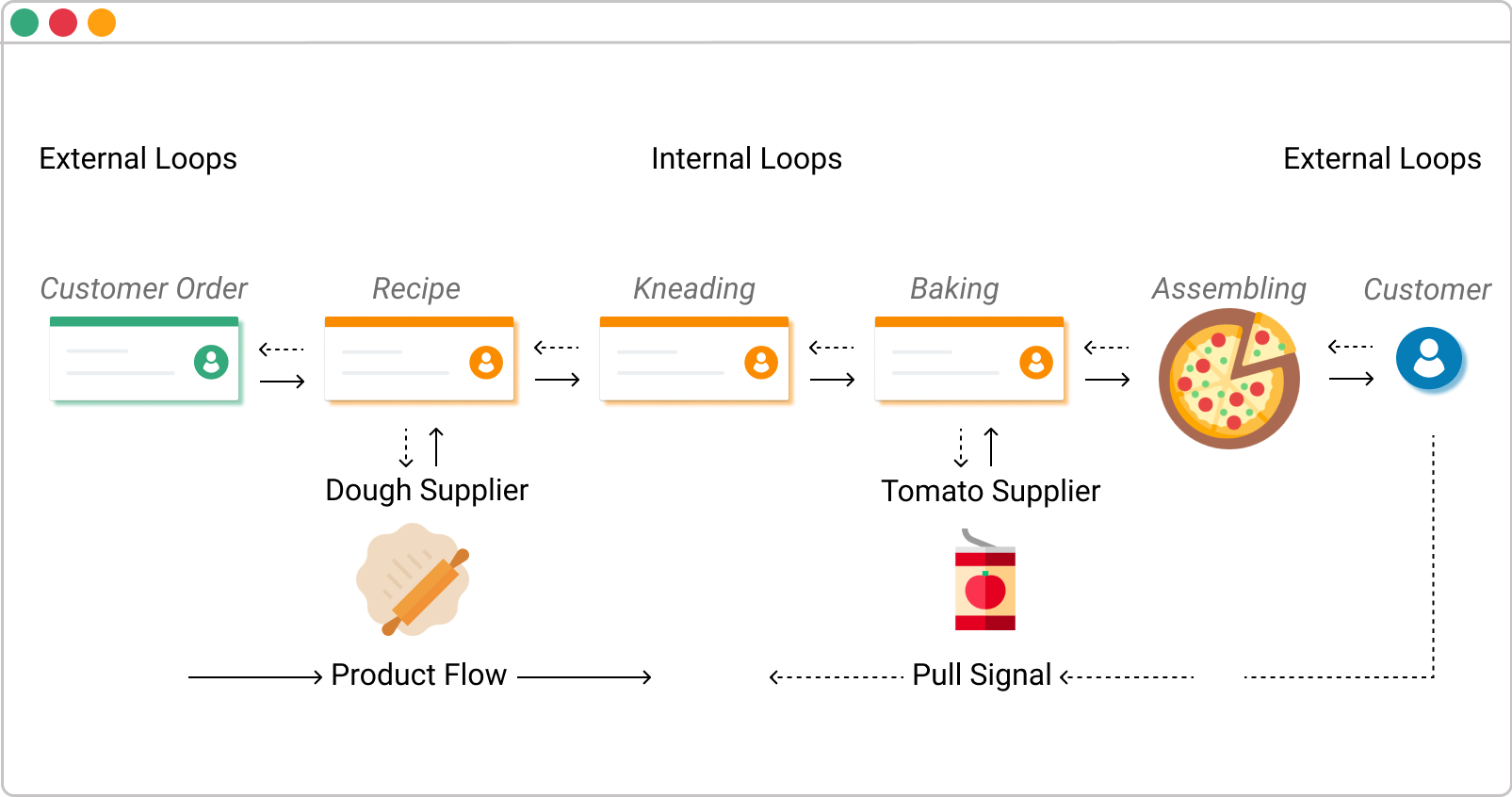

The just in time jit inventory system is a management strategy that minimizes inventory and increases efficiency. The process involves ordering and receiving inventory for production and customer sales only as it is needed to produce goods and not before. Just in time jit manufacturing also known as just in time production or the toyota production system tps is a methodology aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. What is just in time.

However the true potential of this strategy was realized when it integrated this strategy with tps. A production system based on the philosophy of achieving the complete elimination of all waste in pursuit of the most efficient methods. The just in time jit style of inventory management also sometimes referred to as the toyota production system tps is a strategy of managing inventory inventory inventory is a current asset account found on the balance sheet consisting of all raw materials work in progress and finished goods that a company has accumulated. Its origin and development was mainly in japan largely in the 1960s and 1970s and particularly at toyota.

Kanban a technique for work and inventory release is a major component of just in time jit and lean manufacturing philosophy. Toyota began using the just in time method in 1938. Toyota motor corporation s vehicle production system is a way of making things that is sometimes referred to as a lean manufacturing system or a just in time jit system and has come to be well known and studied worldwide. Istilah just in time jika diterjemahkan langsung ke dalam bahasa indonesia adalah tepat waktu jadi sistem produksi just in time atau jit ini.

Companies often store excess product inventory to be responsive to customer demand. Products are produced when they are needed and in the quantity needed.

.jpg)