Sistema Just In Time Toyota

Its origin and development was mainly in japan largely in the 1960s and 1970s and particularly at toyota.

Sistema just in time toyota. Se atribuye al fundador de la marca japonesa sakichi toyota a su hijo kiichiro y al ingeniero taiichi ohno. Origins of just in time management strategy. El sistema de producción de toyota tuvo un origen que merece la pena recordar. Jit focus on reducing inventory and throughput.

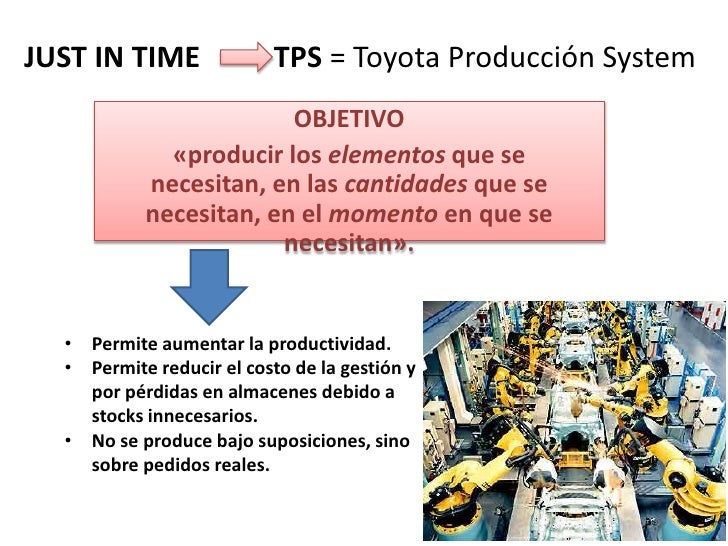

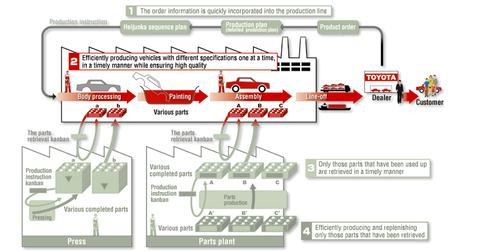

Productivity improvement making only what is needed when it is needed and in the amount needed producing quality products efficiently through the complete elimination of waste inconsistencies and unreasonable requirements on the production line. Toyota began using the just in time method in 1938. The technique of arranging regular small deliveries of exactly the correct amount required was pioneered by toyota. Ellos fueron los verdaderos artífices a los que le debemos hoy en día este sistema jit o just in time.

If you ve ever studied manufacturing it s likely you will have heard of just in time production methods. This is the total time required to complete the production process. Just in time jit manufacturing is also known as the toyota production system. It is widely used to improve operations.

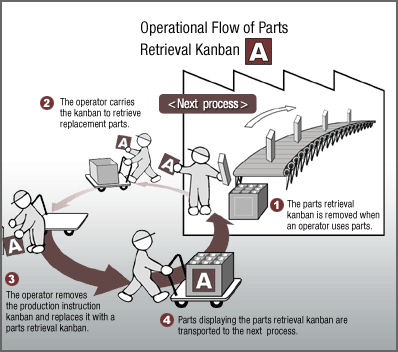

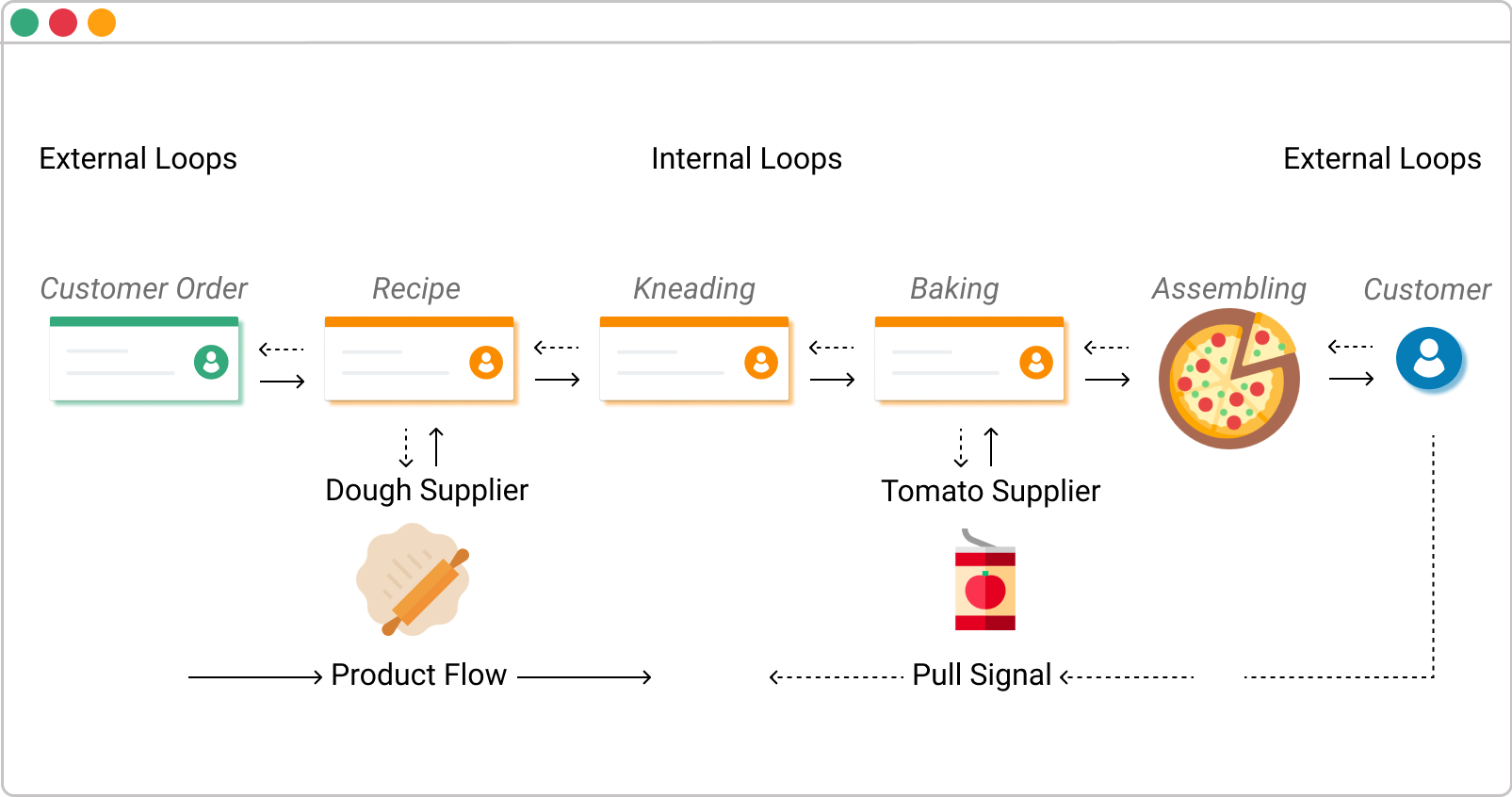

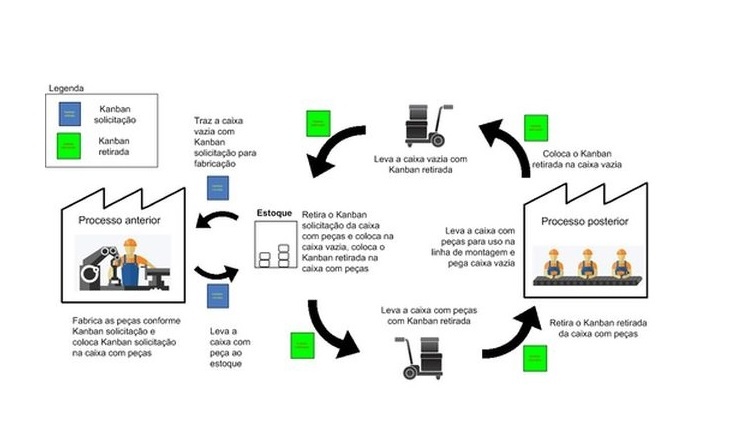

Jidoka which can be loosely translated as automation with a human touch as when a problem occurs the equipment stops immediately preventing defective products from being produced. The toyota production system tps was established based on two concepts. Although the history of jit traces back to henry ford who applied just in time principles to manage inventory in the ford automobile company during the early part of the 20th century the origins of the jit as a management strategy traces to taiichi onho of the toyota manufacturing company. And the just in time concept in which each process produces only what is needed for the next process in a continuous flow.

The just in time jit inventory system is a management strategy that minimizes inventory and increases efficiency. It is the time required to change raw materials to complete products. At the time a sharp decline in auto demand and the high costs of production haunted automakers including toyota. Just in time method.